Keep your production line moving efficiently and safely

Why process management requires heat transfer fluid

The operation of most production lines involves the generation of heat from manufacturing equipment. It may be necessary to maintain control over the temperature of the production lines in order to ensure overheating effects on either the equipment or the product itself are not manifested. Such process cooling is an essential part of the design in these operating systems.

Reports

For more information read our article “Water-Based Heat Transfer Fluids”

By Kilfrost Technical Team

Read the full reportReports

For more information read our article “Choosing the Right Heat Transfer Fluids”

By Kilfrost Technical Team

Read the full report

Alleviate potential problems with Kilfrost ALV

Kilfrost’s revolutionary heat transfer fluid technology provides a compelling commercial solution to long-standing challenges that can hinder production line processing.

Kilfrost ALV is the product of choice to give support to production processes with benefits including reducing operational carbon emissions, enhancing the lifespan of equipment as well as being classified as non-hazardous in accordance with CLP/REACH.

If you are processing Food & Beverage, Kilfrost ALVPLUS can offer you the additional benefit of being certified as safe for incidental food & beverage contact by the US NSF.

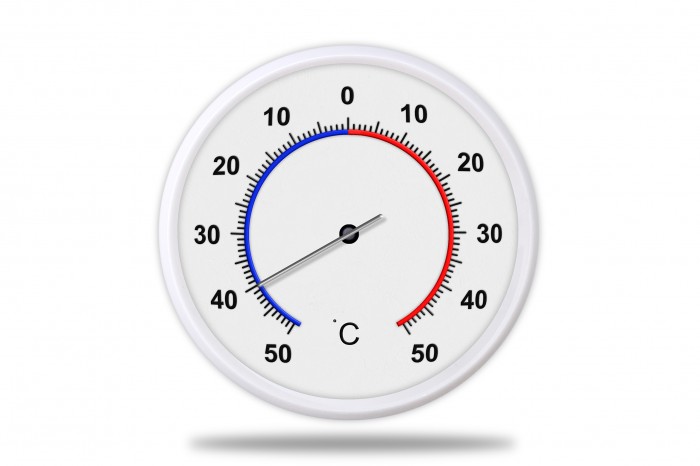

Optimum temperature range

Kilfrost ALV offers more consistent temperature control and thermal power transmission. The optimal temperature operating range is -40°C to 40°C.

Kilfrost ALV contributes to reducing your carbon footprint and helps to deliver your sustainability goals

Do you have issues with pressure drops in your system and high pumping cost?

Kilfrost ALV is an engineered low viscosity fluid which outperforms MEG, MPG, Bio-PDO and ethanol-based heat transfer fluids. The graph opposite shows that as the temperature decrease Kilfrost ALV fluid remains low in viscosity. How does this help you reduce your carbon footprint?

As the temperature decreases, other heat transfer fluid products become more viscous and “sluggish”. Kilfrost ALV fluid remains low in viscosity which means less pumping power is required to circulate the fluid around the system and due to this hydraulic efficiency, it will, in turn, reduce building energy consumption and operational carbon emissions.

Asset protection and lifespan of equipment

Equipment breakdowns and maintenance is a continuous job which can be challenging to manage. This can halt production or limit the capacity of the production line.

You invest heavily in the best quality of equipment, so why fill your system with substandard fluid, which does not provide corrosion protection for your investment.

Kilfrost ALV has been tested to and exceeds the ASTM D1384-05 corrosion standard at 88°C providing outstanding protection for your equipment and pipework. For more information read our article “The corrosion protection properties of heat transfer fluids”.

Why would you choose anything else other than Kilfrost ALV?

Now you have all the information you need to make an informed decision on which heat transfer fluid to use and why.

Reports

The corrosion protection properties of heat transfer fluids

By Kilfrost Technical Team

Read the full report